-

Rasselstein ThyssenKrupp

On December 8, 2024, our group of students went on an educational excursion to Rasselstein ThyssenKrupp, a world leader in tinplate production. The experience of the visit clearly demonstrated how cutting-edge technology, centuries of experience and sustainable business principles can harmoniously coexist in one company.

On December 8, 2024, our group of students went on an educational excursion to Rasselstein ThyssenKrupp, a world leader in tinplate production. The experience of the visit clearly demonstrated how cutting-edge technology, centuries of experience and sustainable business principles can harmoniously coexist in one company. Our day began with breakfast in an atmospheric hostel located within the historic walls of the Ehrenbreitstein Fortress in picturesque Koblenz. The historical setting and stunning views of the city filled us with inspiration even before the excursion began.

Our day began with breakfast in an atmospheric hostel located within the historic walls of the Ehrenbreitstein Fortress in picturesque Koblenz. The historical setting and stunning views of the city filled us with inspiration even before the excursion began. Upon arrival, we were warmly welcomed by company representatives and given a presentation in the conference room, where we were able to delve deeper into the company’s history, values and achievements. Founded in 1760, Rasselstein ThyssenKrupp has grown into one of the key players in the global tinplate market. The company produces 1.5 million tons of tinplate annually, which is widely used for packaging such as cans, aerosols, can lids, industrial packaging and more. The company serves more than 100,000 customers in over 80 countries, and its main markets are: Other EU countries: 39%; America: 27%; Germany: 22%; Asia: 6%; Rest of Europe: 4%; Africa: 2%

Upon arrival, we were warmly welcomed by company representatives and given a presentation in the conference room, where we were able to delve deeper into the company’s history, values and achievements. Founded in 1760, Rasselstein ThyssenKrupp has grown into one of the key players in the global tinplate market. The company produces 1.5 million tons of tinplate annually, which is widely used for packaging such as cans, aerosols, can lids, industrial packaging and more. The company serves more than 100,000 customers in over 80 countries, and its main markets are: Other EU countries: 39%; America: 27%; Germany: 22%; Asia: 6%; Rest of Europe: 4%; Africa: 2%We were particularly impressed by the scale of the company: 2,400 employees work with great dedication to provide their customers with products of the highest quality. The presentation was accompanied by videos, diagrams and product samples, which made it easy to understand how sheet metal is produced. We learned about the varnishing and lamination processes with steel films, as well as how sheet metal is coated with base, top and pigment layers. Remarkably, the drying process is completed in just 10 minutes at a temperature of 210 °C. We also saw how automated packaging machines ensure precise and efficient packaging of sheet metal coils and how an internal transport system optimizes the movement of heavy coils throughout the company.

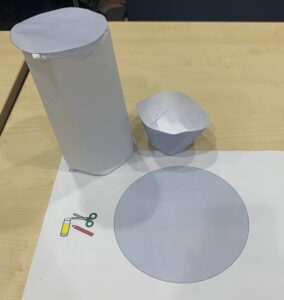

A significant part of the presentation was devoted to sustainability. Rasselstein ThyssenKrupp is committed to minimizing its environmental impact. Tinplate is almost 100% recyclable without any loss of quality. This means that used pet food cans can, for example, be transformed into a car part or even a washing machine component! This commitment to sustainability is especially important as the global demand for environmentally friendly packaging is growing. The company is an example of how innovation can go hand in hand with environmental care. While theory is important, the opportunity to see the production process in action is second to none. We were first tasked with creating paper models of the cans, which required us to use our creativity and logic. Not only was this activity fun, it also gave us a deeper understanding of the complexity of designing tinplate packaging.

We were given safety instructions, given protective gear, and only then were we allowed to enter the production shop. The huge halls, impressive equipment, and unique atmosphere of industrial production left a lasting impression. We were shown every aspect of the process – from the etching lines to the coating units. The highlight of the tour was watching the special forklifts „zebra“ and „cow“, uniquely painted for moving heavy steel coils. In addition, we looked at the company’s new production building, learned about the history of its construction and modern equipment, which further increases the efficiency of work. The day ended with lunch in the canteen, located in one of the company’s historical buildings. During lunch, we discussed the tour, shared ideas and had meaningful conversations with representatives and employees of the company.

We would like to express our sincere gratitude to the representatives of Rasselstein ThyssenKrupp and Prof. Stefan Junge for the unique opportunity to look behind the scenes of one of the most famous manufacturers of tinplate packaging. We not only gained theoretical knowledge, but also invaluable practical experience. This trip was an extraordinary experience and a source of useful information for our future careers. For students who want to build a successful career in the field of packaging technology, such excursions are an unprecedented chance to broaden their horizons and gain insight into their professional development!