-

Schwarz Production is producing for leading retail companies e.g. Lidl, known for its high-quality products and affordable prices. The company’s Ice cream, chocolate and nuts factory is an impressive example of modern technology and innovation in the food industry. Recently, a group of students of BHT were given the opportunity to visit the factory and learn about the latest facts and figures in the industry.

Schwarz Production is producing for leading retail companies e.g. Lidl, known for its high-quality products and affordable prices. The company’s Ice cream, chocolate and nuts factory is an impressive example of modern technology and innovation in the food industry. Recently, a group of students of BHT were given the opportunity to visit the factory and learn about the latest facts and figures in the industry.

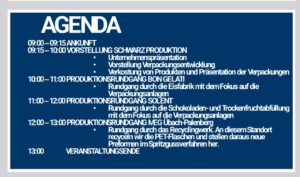

The presentation given to the students by Mr. Holzapfel and Eric Moreno covered a range of topics related to the production of ice cream, chocolate and nuts. The presenter talked about the raw materials used in the production processes. They also discussed the various stages of production to packaging of the final products.

One of the most impressive aspects of the presentation was the discussion of the latest packaging machines used in the factory. These machines are capable of packaging thousands of products per hour, with incredible accuracy and efficiency. They are also designed to reduce waste and minimize the environmental impact of the packaging process.

After the presentation, the students were given a tour to the three factories. They were able to see the production process in action, from the mixing and blending of ingredients to the packaging and labeling of the final products. They also had the opportunity to see the latest packaging machines in action, which was a truly impressive sight.

The factory tour was a unique and educational experience for the students. They were able to see firsthand how ice cream, chocolate and nuts are produced on a large scale and how technology and innovation are transforming the industry. The visit to Schwarz production factory was an excellent example of how modern technology and innovation are driving the food industry forward.

Overall, the visit to the Ice cream, chocolate and nuts factory was an excellent opportunity for the students to learn about the latest trends and innovations in the industry. The presentation and factory tour provided valuable insights into the production process and demonstrated the importance of technology and innovation in the food industry. It was an experience that the students are sure to remember for years to come.

In addition to the three production facilities, the students also visited a PET bottle recycling plant. At the recycling plant, they learned about the importance of recycling and how the plant processes used PET bottles into new products. The plant uses advanced technology to sort, clean, and shred the bottles, turning them into small flakes. These flakes are then melted down and injection-molded into new pre-forms which would turn into „new“ plastic bottles made from 100 % PCR material. The visit to the recycling plant was a great opportunity for the students to see how waste can be transformed into new products, and the importance of sustainable practices in the production and consumption of goods.

In addition to the three production facilities, the students also visited a PET bottle recycling plant. At the recycling plant, they learned about the importance of recycling and how the plant processes used PET bottles into new products. The plant uses advanced technology to sort, clean, and shred the bottles, turning them into small flakes. These flakes are then melted down and injection-molded into new pre-forms which would turn into „new“ plastic bottles made from 100 % PCR material. The visit to the recycling plant was a great opportunity for the students to see how waste can be transformed into new products, and the importance of sustainable practices in the production and consumption of goods.Thanks to all – and for the great food and drinks, too !!!